Product Description

The belt carcass of this product is EP fabric(D.S.EP or CC56) of high modulus,low shrink,and high breaking tensile strength.Cover rubber of this product uses SBR, CR, EPDM rubber or Chloroprene rubber that has very good high temperature resistance.The belt is made with extra care after mixing rubber with high temperature resistant materials, assembling and vulcanizing.

The carcass of this product has very high adhesion after the special treatment of coating and shaping.Under normal working temperature of below 180ºC, the belt is low in elongation, excellent in anti-abrasion,and can bear 250ºC(in the cooling condition, 300ºC-600ºC) high temperature for a short time.The belt is suitable for use in cement,metallurgical and steel industry.

Features & Advantages

1,Heat-resistant cover resists cracking and hardening

2,High-temperature resistance to tearing and abrasion

3,High strength carcass construction

4,The carcass with heat-resistant material

Application Fields

Metallurgy, steel plant, building material and construction, energy, chemical,machinery equipment and port.

Execution standard

GB/T20021-2005

Tensile Strength & Width

Tensile Strength:300~3200 N/mm Width:500~2400 mm

Layer bonding strength of different grades of heat resistance in the tropics at their respective temperatures

| Item | Between Piles | Between Cover and Belt Carcass |

| Average of all samples | 2.1 | 2.1 |

The all samples' lowest peak value is not less than | 1.6 | 1.6 |

In the fabric with natural fiber to do with the core, with the interlayer adhesion strength

| Item | Between Piles | Between Cover and Belt Carcass |

| Average of All Samples | 3.2 | 2.7 |

| The all samples' lowest peak value is not less than | 2.7 | 2.2 |

Abrasion between Piles

| Item | Between Piles | Between Cover and Cloth | ||

| Cover Thickness<=1.5mm | Cover Thickness >1.5mm | |||

| Chemical Fiber Filement Fabric Carcass | Longitudunal Average Value ≥,N/mm | 4.5 | 3.5 | 3.5 |

| Longitudinal Lowest Peak,N/mm | 3.9 | 2.9 | 2.9 | |

After the high temperature resistance belt heating test,its physical and mechanical performance should be in accordance with the provisions below.

| Item | Type | ||||

| T1 1 | T2 2 | T3 3 | T4 4 | ||

| Variation Range | |||||

| Hardness | Differences before and after Aging | +20 | +20 | ±20 | ±20 |

| Maximium Value after Aging | 85 | ||||

| Tensile Strength | Change Rate after Aging | 12 | 10 | 5 | 5 |

| The Minimum Value after Aging | -25 | -30 | -40 | -40 | |

| Elongation | Performance Change Rate | -50 | -50 | -55 | -55 |

| Minimium Value after Aging | 200 | 200 | 180 | 180 | |

Physical Performance

| Item | ||

| Hardness | Differences Before and after Aging(IRHD) | ±20 |

| After Aged Maximum Value(IRHD) | 85 | |

| Tensile Strength | The Performance Rate of Change Reduces,% | -40 |

| After Aged Minimum Value,Mpa | 5 | |

| Elongation | Change Rate of Performance Reduces,% | -55 |

| After Aged Minimum Value,% | -180 | |

Adhesion strength between layers of fabric with natural fibers

| Item | Between Piles | Between Cover and Belt Carcass |

| Average of All Samples | 4.5 | 3.5 |

| The all samples' lowest peak value is not less than | 3.9 | 2.9 |

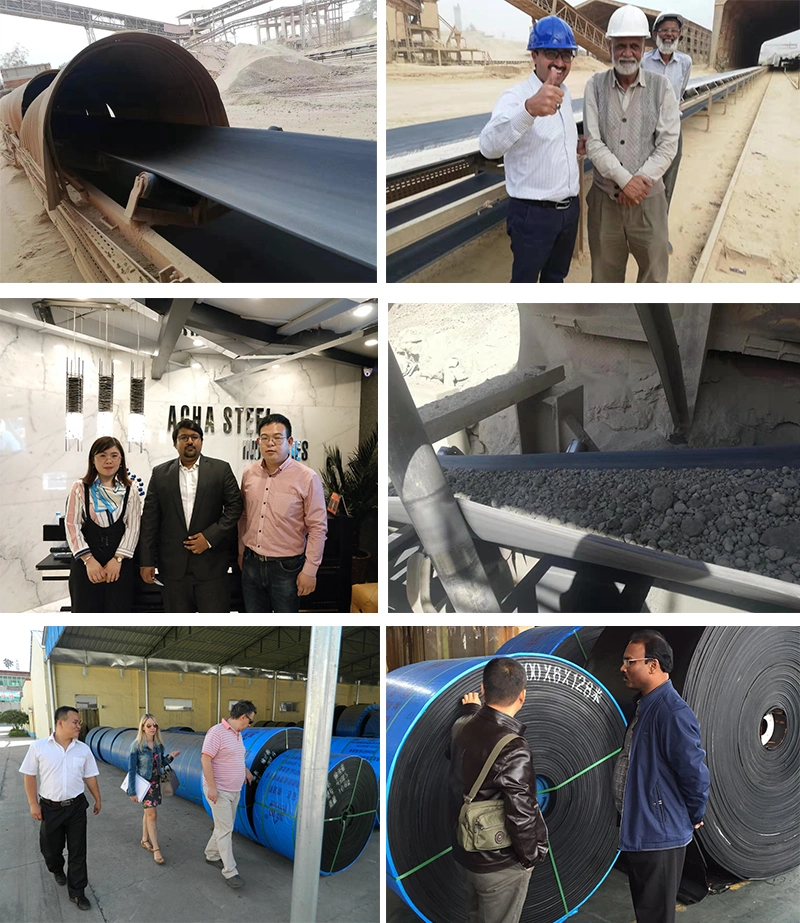

Hebei Lanjian Rubber Belts Co., Ltd is a medium-sized rubber belts manufacturing enterprise with "Lanjian" series conveyor belt as its leading products.

Our advantages :

1. More than 30 years experiences

Our company was established in 1998,the registered capital is RMB100 million yuan.

2. First-class producing equipment and management system

We have more than 8 conveyor belt production lines, and advanced DrumType vulcanizing machine.

3. Products are certified with ISO9001 standard

We have ISO 9001 Quality Control System, ISO14000 Environment Management System and GB/T28001 Occupational Health&Safety Management System, Measurement Management System, State Standardization Good Compliance Certificate.

4. Strong technical support and R&D capacity

We have a separate design, research and development capability and can be customized according to customer demand.

Our company possesses a complete set of detection apparatus, the independent chemical analysis and physical labs, ensuring all the raw materials. Semi-products and finished products are under control and there no unqualified materials and no unqualified product.

Our major products include: normal conveyor belt below B2400MM, NN/EP conveyor belt, PVC PVG fire resistant conveyor belt, large dip angle conveyor belt, acid&alkali resistant conveyor belt, patterned conveyor belt, oil-resistant conveyor belt, steel cord anti-tear conveyor belt, ring conveyor belt, roller, pulley,etc.

We offer a variety of packing solutions, it can also be customized according to your requirements.

Our products have well sold domestic and abroad including Southeast Asia, Russia, Africa, Australia, Latin America and so on.

1. Pre-sales service

* Inquiry and consulting support

* Sample testing support

* View our factory

2. After-sales service

* We provide 24hour/7days after-sales service

* Regularly visit our client and keep quality tracking

3. One year warranty

No damage to human factors, one year warranty, life-long maintenance.